This set of photographs is to supplement those in Mark Ketchum's photo gallery and to point out special problems in shell design or construction.

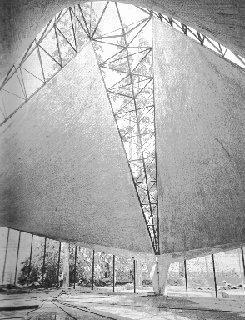

This is a poor photo but it brings up an important problem. The structure is a short shell for a bakery. The span of the frames that support the shell is 85 feet and the distance between frames is 35 feet. There are four frame in a series. The shell thickness is 2 in. at the center and 3 in. near the valleys. Notice the white streaks on the underside of the shell. They occur where the frames are above the shell. In these areas the concrete is 3 ft. thick and is much denser than for the 3 in.shell. The concrete in shells is not compacted in the way thick concrete members are. Design stresses is shells should be very conservative. Shells get their strength by shape and form, not by the strength of the material.

This is the previous shell under construction showing the form work. It is movable and slids on wooden rails on the ground, except for the center which is fixed. This was done so the movable form could be decentered and moved sooner. Concrete should be supported as long as possible.

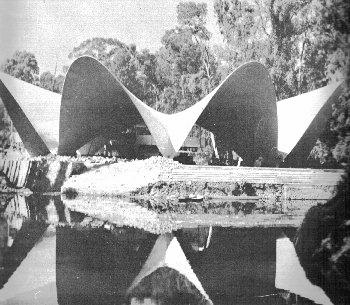

This is a picture of the famous shell by Felix Candela in Xochimilco, Mexico, and covers an area of 150 feet round. Candela was a master of geometry. To create a shell with minimum streses, the shell must have double curvature in all areas. If this is done, then the calculation of stress is merely incidental.

The photograph of another shell by Candela shows a dome made from three hyperbolic paraboloidal units separated by skylights. The curvature of the hypars is not as great as the previous example so he was more conservative. Note the steel columns under the edges. Deflections are a constant problem with so thin members.

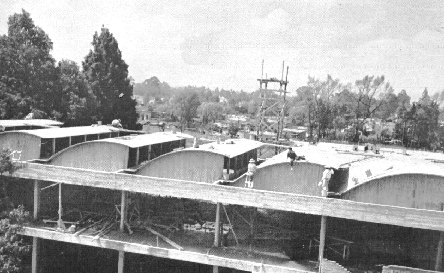

Candela is best known for his many hyperbolic paraboloids, but he was the master of all types of shells. Here is group picture of a brewery in Mexico. There are both short shells and translation shells. The open architecture promotes the appearance of extreme lightness.

The use of north light shells has not generally been accepted in this country. The argument is that the light is variable, and therefor you will need artificial illumination anyway. Any one who has worked under natural light knows that this theory is not valid. Changes in lighting for various conditions gives relief to the worker. There are other problems, however, spill of cold air from ovehead windows may be a problem in cold climates. Also the acoustics of the curved surfaces need to be solved. The next picture is of north light barrel shells by Felix Candela in Mexico.

One unit consists of a gutter to collect the rain and a barrel, with large slanting windows between each unit. The windows therefore support the high point of the barrel. Remember that Candels's shells are all only an inch and a half thick

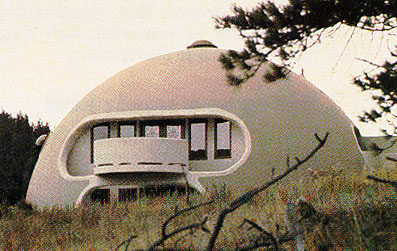

The construction of airformed shells is a growing industry in this country. The photograph is of a house and was save from a website entirely devoted to dome constructors. I selected this picture from one of the references

Here is another dome use for bulk storage. My son, Mark Ketchum, a Principal of OPAC Engineers, San Francisco, was the engineer of record.