READERS COMMENTS

COMMENT NUMBER 1

Dear Mr. Milo Ketchum,

We are two Italian Civil Engineering students; we were searching on

the web for information about concrete shells, when we found your web

site. Alas! We couldn't find any other site as interesting, detailed and

exhaustive as yours.

We are designing a concrete shell (an hyperbolic paraboloid), inspired

on Candela's "La Capilla de Nuestra Senora de la Soledad" known as "El

Altillo Chapel", so we were very pleased to see that your site is full

of Candela's works.

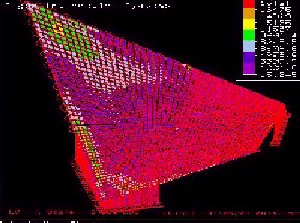

We attach to our message a picture of the model we used to analize our

shell with a FEA program, SuperSAP. It is a self-extractor file.

The shell is supported by concrete walls and metal pillars (represented

by circles on the edge of the shell). There is a beam running along the

edges of the shell: it is 10 inch wide and its height changes from 32 to

7 inch. The window top-right gives the stresses in KN/m^2 (Von Mises

criterion).

The stress pattern is not simmetric because of the wind blowing from one

side.

The shell is 112 feet long and 89 feet wide. It is 4 inch thick.

We had some problem while calculating the steel reinforcement. The main

problems were on the edges of the shell and next to the concrete walls.

Unfortunately in Italy there are no specific regulations (or books) on

the matter. We wonder if you could suggest us where to find information

(in your site you talk about American Concrete Association regulations:

do they have a web site with these rules?) or if you may personally help

us.

Thank you very much for your time.

We hope to hear from you soon.

Alessandra Pasqua, Guido Maccone

Dear A and G

A characteristic of Candela's shells is that they are pecularily fitted

to be built in snow less climates. The edge members in these climates

take less thrust and therefore may be made smaller, so that the

torsinal stresses are less. I know. The only failure I had was in a a

"saddle hypar" in an edge member due to torsion. The next hypar we

prestressed all the members, and it has been completely sucessful. Look

at the "Broadmoor Shell" in "A Short Tutorial".

This is your chance to solve that problem. One answer is to make the

shell thicker at the supports, thus reducing the torsion. I have always

wanted to analyse Candela's shell by FEM. The only problem he ever

mentioned to me was a torsional failure at supports of the shell for the

Bourse (stock exchange).

REPLY