| Mark Ketchum's Concrete Shell Photo Gallery |

| Mark Ketchum's Concrete Shell Photo Gallery |

The page is currently organized into the following categories:

It will get more categories as it grows.Click on any photo or its title for a high resolution version.

|

| |

|

Hyperbolic paraboloid for church in Boulder Colorado

This structure is unique in that the longitudinal central ridge is lower than the peak of the arches. This construction view shows the steel ties to connect the springs of the triangular arches that will subsequently be concealed by the colored glass brick filler walls. The concrete on the steep slopes was placed by the shotcrete method. |

|

Barrel Shell for Bakery

This roof system has multiple bays in each direction. A unit is composed of two circular elements as shown. The shell was formed with a fixed form at the small circle at the columns and a movable form for the large circle. There are no horizontal ties at the columns. Shells are ideal for bakeries because of the hard surfaces and few horizontal surfaces to catch dust. |

|

Folded plate roof for gymnasium and cafeteria

There are windows between the tilted Z shaped elements to provide overhead natural light. There are two spans of about 50 and 60 ft. The supports at the ends of the elements are arranged to make it appear that the roof floats on its supports. The shell thickness is three inches. |

|

Hyperbolic Paraboloid Roof for Entertainment Center

This roof in this construction picture is about 185 ft. square, and is supported on steel tripod elements. In plan, the structure is not square but has eight sides, so the length of the top rib is roughly the same length as the sloping side ribs. This is to avoid the box like roof of a square roof plan. The structural ribs, however, are on square plan. The roof thickness is 3 inches, except for the ribs. |

|

Barrel shell for small office

This structure has a clear span of 40 feet with large windows for north light on work surfaces. The upturned shell at the entrance is supported at the middle by columns so it does not have to span the entire 40 feet, and can be made smaller. The projections of the shell beyond the walls do not have any roofing to show that the thickness of the shell is small. |

|

Folded plate for gymnasium

The folded plates are the typical two-element construction. North light is achieved in this roof structure by truss elements cast in the plates. The edge plates are small because they are supported by columns. |

|

Domes for a shopping center

These translation domes are each about 40 feet square. and are there four elements in one direction and nine in the other. There are no interior ties at the springing of the domes and thrusts are carried by diagonal braces at the exterior. Movable forms were used and units were four elements wide. Each element was formed by four bowstring trusses which could be reused for a typical bowstring industrial building. |

|

Construction view of small hangar for business airplane

This structure is a cylinder, square in plan. The rear rib is supported by columns, and the front rib is essentially an arch supported at the abutments, and at the crown, laterally, by prestressing cables running across the top of the shell. |

|

Folded plate for small gymnasium

The slab elements on this roof are haunched. The span is about sixteen feet and the thickness at the ridge and crown is eight inches tapering to three inches in about five feet. Note the steel columns to support the edge members and reduce their size. These will be covered in the walls. |

|

Folded plate for equipment display area

This is a single element with glass walls on three sides. The edge members are supported at the center to avoid excessive deflections on the relatively shallow upturned edge elements. |

|

Small warehouse with a folded plate roof

This structure is a complete box with tilt-up walls. |

|

Circular church building with folded plate roof

There is a circular wall at the middle of the structure and the folded plates taper to this wall, making the depth at the center half the depth at the ends. |

|

Barrel shell roof cover for swimming pool

|

|

Short shell for auditorium, Chase Hotel, St. Louis

The frame supporting the shell is a arch supported on one end by a vertical column. For acoustic purposes, the shell is penetrated by holes leading to acoustic insulation, all covered with a timber false roof. |

|

Precast shells to cover a water canal in the mountains

The shells are cast on an initial form and then placed layer on layer with a bond breaker between. All vertical dimensions are the same. |

|

Planetarium in Forest Park, St. Louis

The basic shape is a paraboloid of one sheet, generated by a non vertical line moving around a cylinder. Within the structure, there is the conventional spherical screen with access to a platform above to see the actual stars. |

|

Bank building in Casper Wyoming

The roof is composed of precast curved elements assembled in a circle. The initial form was sculpted from earth. |

|

| |

|

Felix Candela |

|

Construction photograph of an inverted umbrella shell roof

Note the careful placement of the reinforcing; every intersection is tied. Candela's shells were universally 1.5 inches thick, (4 centimeters), two layers of #3 bars with 3/8 inch cover (one centimeter). These structures were ordinarily about 56 feet square, with a slope from the edge to the center of 7 feet. He was quoted as saying that he could not charge what these structures cost, they would be too far below the competition. |

|

Short shells used for produce market

A short shell has a large radius compared to is length. It is supported by arches or frames. The framing for these structures is a column with the horizontal thrusts carried by horizontal ties above the roof. Each unit consists of two frames, with a skylight between. |

|

Hyperbolic paraboloid roof for a warehouse

Each unit is about 55 fit. by 33 feet in plan, and has a rise of 7 feet. The units are tilted to allow northlight windows. |

|

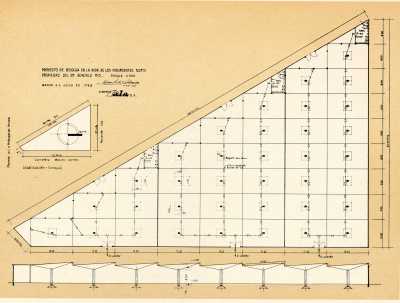

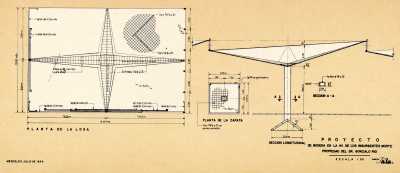

Drawing of hyperbolic roof structure

This drawing shows details of the previous structure. Note the use of hypars for footings. Again the thickness of the shell is 1.5 inches. From ENR, May 1955 |

|

Drawing of hyperbolic roof structure

Another drawing showing more details of the previous structure. From ENR, May 1955 |

|

Church of the Virgin Milagrosa, Mexico City

The walls of the hyperbolic paraboloid structure are almost vertical, and are in effect, essentially, plastered, with the reinforcing holding the concrete in place. |

|

Feliz Navidad Y Año 1967

No chimney on the shell roof! |

|

| |

| St. Louis Airport

Designed by Anton Tedesko Outside view A Cylindrical Groin Vault |

|

| St. Louis Airport

Designed by Anton Tedesko Panoramic view A Cylindrical Groin Vault |

|

| St. Louis Airport

Designed by Anton Tedesko Inside view A Cylindrical Groin Vault |

|

|

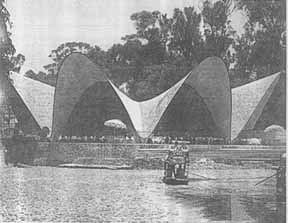

Restaurant Los Manantiales

Xochimilco, Mexico Designed by Felix Candela, 1958. Outside view A Hyperbolic Paraboloid Groin Vault |

|

Restaurant Los Manantiales

Xochimilco, Mexico Designed by Felix Candela, 1958. Inside view A Hyperbolic Paraboloid Groin Vault |

|

Computer Renderings

Of a Hyperbolic Paraboloid Groin Vault ( by Volker Ruhl and Larry Burks ) Wire Frame, Outside, and Inside |

|

Pittsburg Marine Terminal

Petroleum Coke Bulk Storage Pittsburg, California Designed by OPAC Consulting Engineers, 1997. Built by Dome Systems, Inc. Outside view Three 180 ft diameter hemispheres |

|

Los Angeles Export Terminal

Petroleum Coke Bulk Storage Terminal Island, Los Angeles, California Designed by OPAC Consulting Engineers, 1999. Built by Dome Systems, Inc. Two 240 ft diameter hemispheres. Inflated airform for the first dome (with construction acivities under way inside) is in the background. The footer and stem wall for the second dome are in the foreground. |

|

Los Angeles Export Terminal

Airform being inflated. This operation took about 1.5 to 2 hours for this 240 ft diameter dome. The Vincent Thomas Bridge is visible in the background. An uncovered coke pile is visible just behind the dome; blowing particles from this uncovered pile have discolored the airform. |

|

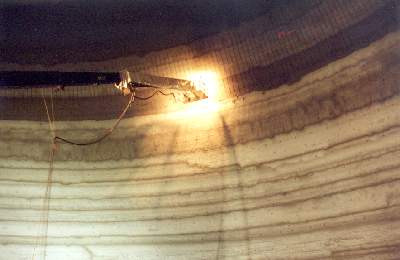

Los Angeles Export Terminal

Shotcrete application inside the dome. The dome is fairly dark inside, so the area illuminated by floodlights on the rotating boom is somewhat over exposed in this photo. The reinforcement being covered in this operation is visible above the dark spray line. |

|

Los Angeles Export Terminal

Light shines through a ventilation hole near the top of the dome during construction. The shotcrete boom is visible in the foreground. The lighter area near the top has not yet been concreted, so light shines through the airform and foam. The lower reaches of the shell are being concreted. |